Autoclave Sterilization

Automatic Autoclave

The vertical pressure steam sterilizers are assembled with a heating system, micro-computer-controlled system, overheat, and overpressure protection system, which is reliable for the sterilizing effects, convenient operation, and energy conservation. They are ideal equipment for clinics, scientific research institutes, and other organizations to sterilizer surgical instruments, fabrics, glasses, culture media, etc.

Characteristics:

– Fully stainless-steel structure.

– Handwheel type of quick-open door structure.

– Door safety lock system.

– LCD display of working status, touch type key.

– Auto discharge the cool air and stem discharge automatically after sterilization.

– Over-temperature & over pressure auto-protection.

– Safe protection of water laking.

– Self-inflating type seal.

– Automatically shut off with beep reminding after sterilization.

– Easy to operate, safe, and reliable.

– With two stainless steel sterilization baskets.

– With drying system.

Specification:

Model | LS-35HD |

Sterilizing volume | 35L |

Working Pressure | .22Mpa |

Working Temperature | 134°C |

Max Safety Pressure | 0.23Mpa |

Heat average | ≤ ± 1°C |

Timer Range | 0-99min or 0-99hours 59min |

Temp. Adjust range | 105-134°C |

Power | 2.5Kw/AC220V 50Hz |

Transport dimension | 570x550x1150 |

G.W/N.W | 72/56kg |

Ethylene Oxide

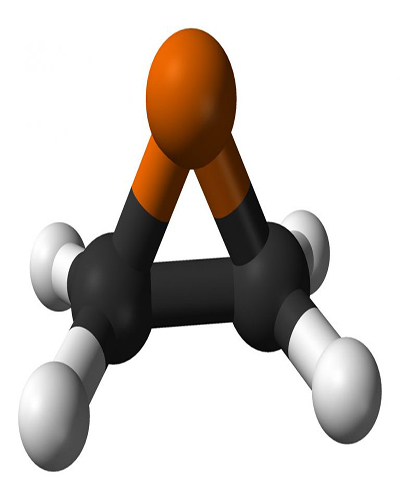

Ethylene oxide is a surface disinfectant that is widely used in hospitals and the medical equipment industry to replace steam in the sterilization of heat-sensitive tools and equipment, such as disposable plastic syringes.

| |||

| Names | |||

|---|---|---|---|

| Preferred IUPAC name Oxirane[1] | |||

| Systematic IUPAC name Epoxyethane Oxacyclopropane | |||

| Other names Ethylene oxide Dimethylene oxide 1,2-Epoxyethane [3]-crown-1 Epoxide | |||

| Identifiers | |||

3D model (JSmol) | |||

| Abbreviations | EO, EtO | ||

| 102378 | |||

| ChEBI | |||

| ChEMBL | |||

| ChemSpider | |||

| ECHA InfoCard | 100.000.773 | ||

| EC Number |

| ||

| 676 | |||

| KEGG | |||

| MeSH | Ethylene+Oxide | ||

PubChem CID | |||

| RTECS number |

| ||

| UNII | |||

| UN number | 1040 | ||

CompTox Dashboard (EPA) | |||

| Properties | |||

| C2H4O | |||

| Molar mass | 44.052 g·mol−1[2] | ||

| Appearance | Colorless gas | ||

| Odor | Like diethyl ether[3] | ||

| Density | 0.8821 g·cm−3[2] | ||

| Melting point | −112.46 °C (−170.43 °F; 160.69 K)[2] | ||

| Boiling point | 10.4 °C (50.7 °F; 283.5 K)[2] | ||

| Miscible | |||

| Vapor pressure | 1.46 atm (20 °C)[4] | ||

| −30.5·10−6 cm3/mol[5] | |||

Refractive index (nD) | 1.3597 (589 nm)[2] | ||

| 1.94 D[6] | |||

| Thermochemistry | |||

Heat capacity (C) | 47.9 J·mol−1·K−1[7] | ||

Std molar entropy (S⦵298) | 242.5 J·mol−1·K−1[7] | ||

Std enthalpy of formation (ΔfH⦵298) | −52.6 kJ·mol−1[7] | ||

Gibbs free energy (ΔfG⦵) | −13.0 kJ·mol−1[7] | ||

| Hazards | |||

| Occupational safety and health (OHS/OSH): | |||

Main hazards | Carcinogen Extremely flammable | ||

| GHS labelling: | |||

| |||

| H220, H230, H301, H314, H331, H335, H336, H340, H350, H360FD, H372 | |||

| P202, P210, P260, P280, P301+P310+P330, P303+P361+P353, P305+P351+P338+P310, P410+P403[8] | |||

| NFPA 704 (fire diamond) | |||

| Flash point | −20 °C (−4 °F; 253 K)[6] | ||

| 429 °C (804 °F; 702 K)[6] | |||

| Explosive limits | 3 to 100% | ||

| Lethal dose or concentration (LD, LC): | |||

LC50 (median concentration) | 836 ppm (mouse, 4 hr) 4000 ppm (rat, 4 hr) 800 ppm (rat, 4 hr) 819 ppm (guinea pig, 4 hr) 1460 ppm (rat, 4 hr) 835 ppm (mouse, 4 hr) 960 ppm (dog, 4 hr)[9] | ||

| NIOSH (US health exposure limits): | |||

PEL (Permissible) | TWA 1 ppm 5 ppm [15-minute excursion][4] | ||

REL (Recommended) | Ca TWA <0.1 ppm (0.18 mg/m3) C 5 ppm (9 mg/m3) [10-min/day][4] | ||

IDLH (Immediate danger) | Ca [800 ppm][4] | ||

| Safety data sheet (SDS) | ICSC 0155 | ||

| Related compounds | |||

Related heterocycles | Aziridine, Thiirane, Borirane | ||

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |||

Plasma Autoclave

Plasma Autoclave LPA-B30 is a fully automatic sterilizer with a 60L capacity. It uses 60% hydrogen peroxide at a temperature range of 50 ± 5℃ for sterilization. An advanced vacuum pump ensures high vacuum and corrosion resistance for lasting performance. This autoclave has a rectangular alloy chamber that provides uniform temperature and effective H2O2 diffusion. It offers PLC-based control and a 7-inch color touchscreen for easy operation. Our plasma autoclave loading method

includes two layers of aluminum alloy plates for efficient organization.

Features :

Equipped with biological indicator cultivator

Built-in printer

Multiple protective functions

Includes a safe electric door with a double-layer seal

Rotary vane vacuum pump

Phase sequence protector

Oil mist filter

Heating System

Specifications :

Type Fully automatic | Type Fully automatic |

Capacity 60L | Capacity 60L |

Sterilization Temperature 50 ± 5℃ | Sterilization Temperature 50 ± 5℃ |

Sterilization Agent 60% H2O2 | Sterilization Agent 60% H2O2 |

Fast sterilization≤25min | Fast sterilization≤25min |

Standard sterilization≤35min | Standard sterilization≤35min |

Enhanced sterilization≤55min | Enhanced sterilization≤55min |

Sterilization Cycle | Sterilization Cycle |

Filling Method Cassette, 12 vials of H2O2 / cassette | Filling Method Cassette, 12 vials of H2O2 / cassette |

Master Controller PLC control | Master Controller PLC control |

Display 7-inch color touchscreen | Display 7-inch color touchscreen |

2 layers of aluminum alloy punching | 2 layers of aluminum alloy punching |

plate loaded with sterile items Loading Method | plate loaded with sterile items Loading Method |

Biological monitoring of Bacillus | Biological monitoring of Bacillus |

subtilis and Bacillus | subtilis and Bacillus |

stearothermophilus | stearothermophilus |